ESD Flooring: What is an ESD antistatic floor?

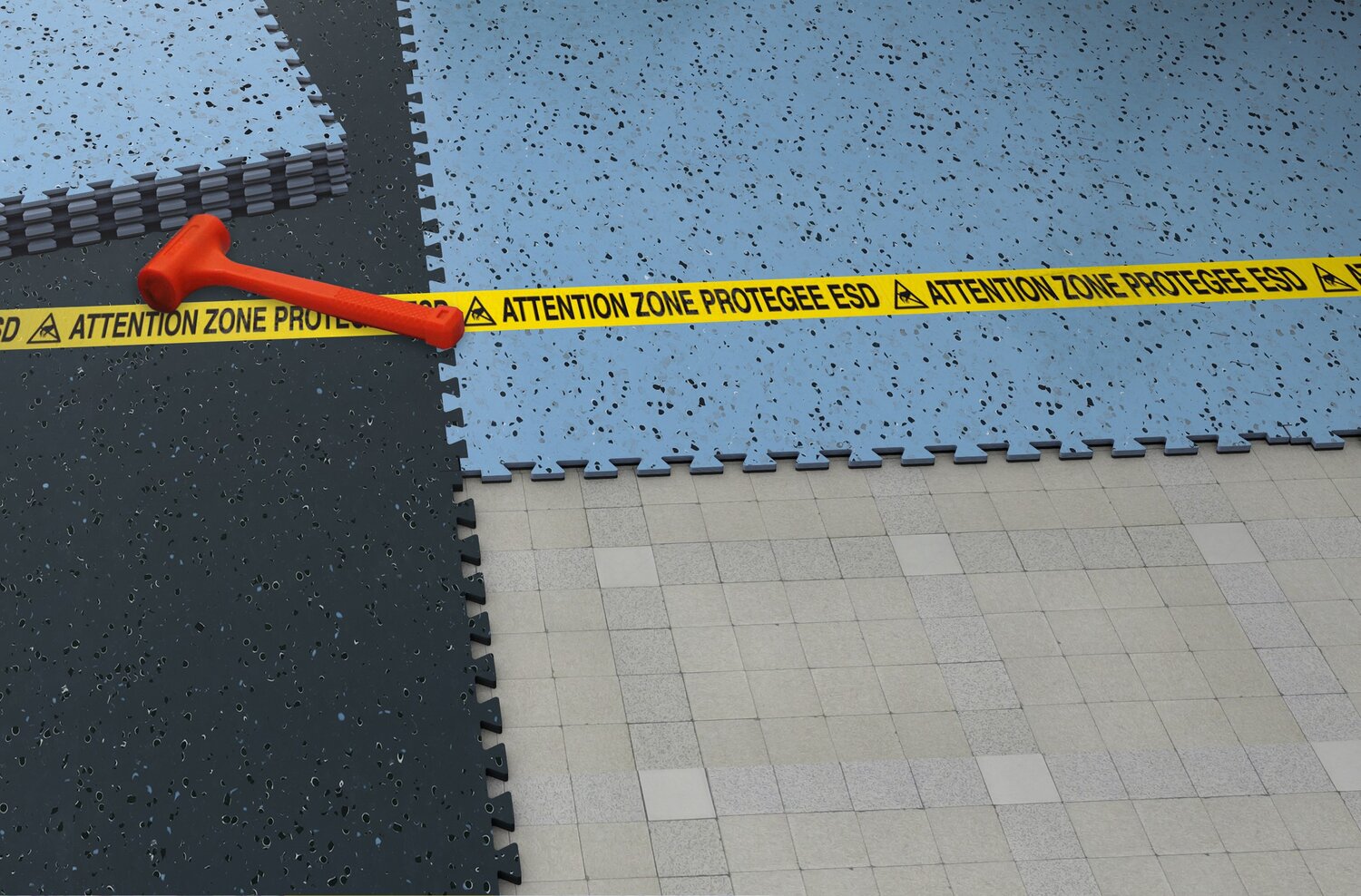

In some sensitive areas in industry environments like electronic assembly lines, semi conductors production, or sometimes in healthcare facilities, electrostatic discharge phenomena needs to be controlled to avoid risks of explosion or risks of damaging electronic devices.

In such cases, flooring plays a critical role to control ESD.

What is ESD?

Before defining the role of an ESD floor, it is appropriate to explain what an electrostatic discharge is. The ESD phenomenon refers to the electrostatic discharge that occurs when electrical charges accumulate on the surface of a material or a human. A discharge occurs when these charges find access to the ground or another unbalanced element. Typically, the electrostatic discharge felt when one has just walked on a carpet and then grabs a doorknob.

Very often the explanation of this phenomenon is seen from the angle of discharge, but there is no discharge without charge. The observation of charging phenomena (measured in Volts) is as important as the measurement of the discharge phenomenon (measured here by resistance in Ohms).

What are the risks associated with ESD phenomena?

ESD phenomenon-related risks can be categorised into two families: those related to people protection and those related to electronic devices protection.

Firstly, people protection aims to control and avoid electrostatic discharges to prevent fires and explosions (e.g., in ATEX environments) in production conditions that present risks associated with vapours, gases, powders, and flammable liquids.

In hospital environments, controlling the ESD phenomenon is crucial to prevent potential damage to equipment (MRI, scanners, etc.), protect against possible explosion risks related to aesthetic gases (which is less and less the case nowadays), and avoid dust accumulation for maximum hygiene.

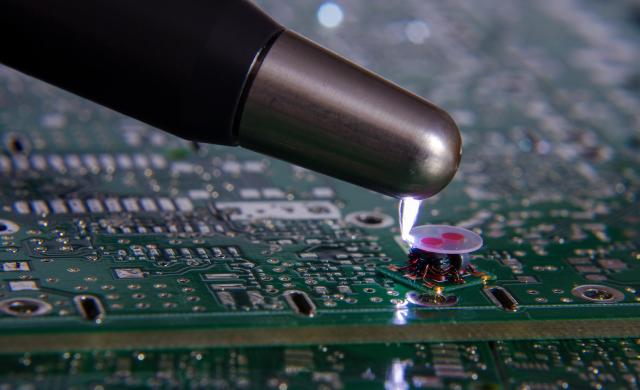

Regarding industries, a human being feels electrostatic discharges starting from 3000 Volts, but certain electronic devices (printed circuit boards, semiconductors, etc.) can be affected by powers below 100 Volts, even below 10V for very sensitive ones. This can have a direct impact on non-quality directly on the production line, but also create weaknesses and latent failures that will impact the device’s performance, or even significantly limit its lifespan. As an example, we cannot afford to send a satellite into space with a potentially defective electronic circuit board.

ESD floors, how to monitor their performance?

Before discussing flooring solutions, controlling ESD phenomena in an environment must be part of a comprehensive control plan that includes grounding of all equipment (workbenches, tools, castor chairs, etc.), grounding people (PPE, ESD shoes, ESD wristbands, gloves, etc.), ionisation of workstations, staff training, and regular audits.

Firstly, an ESD floor is only useful if operators use ESD shoes (man, ESD shoes, and floor system) or other systems that allow personnel to be grounded through the floor. Flooring being the last line of defence for eliminating and conduction of charges to the ground in an ESD system.

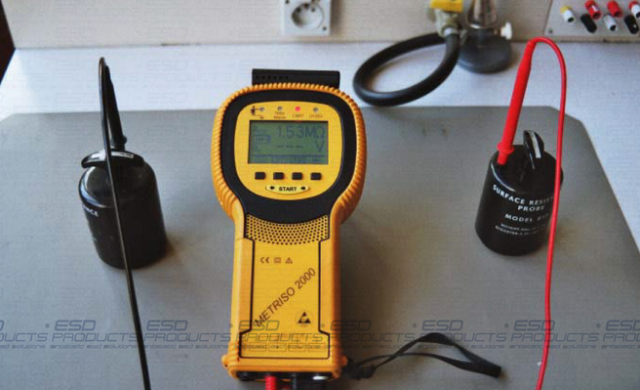

To measure performance, a normative reference and structured test procedures are obviously required. A company willing to set up an EPA (Electrostatic discharge Protected Area) must first choose and define the standard most suitable to its environment. There are many standards related to either applications and/or geographical areas: EN14041, IEC 61340, ANSI ESD S20.20, etc.

Two factors are measured according to ESD standards:

ESD and antistatic floors, making the right choice

As previously mentioned, the choice of flooring solution will first be based on the ESD standard selected and adapted to your organisation. However, the choice of flooring must also be guided by its use and installation conditions:

Contact our Industry experts

Do you have a project in the Industry sector?

Get in touch with our experts for information and advice on Gerflor solutions for the Industry sector.

Thank you for your enquiry!

We will analyse your enquiry and one of our Industry specialists will be in touch with more information or specification advice.